Las máquinas de corte láser son algo mágicas ya que pueden cortar a través de una amplia variedad de materiales con un haz de luz concentrado. Tanto individuos como empresas utilizan estas máquinas para muchos otros propósitos, como fabricar productos en fábricas y crear arte y manualidades exquisitos. Para funcionar correctamente, una cortadora láser tiene muchos componentes esenciales que deben colaborar funcionando armoniosamente.

La primera parte de la que hablaremos es el tubo láser. Este es un componente vital porque aquí es donde se produce el haz láser. El haz láser se mueve a través de una cadena de espejos que lo guían hacia el material que se está cortando. Los espejos están conectados a una sección móvil llamada puente. Este puente mueve los espejos para dirigir el haz láser donde sea necesario, asegurándose de impactar el material donde debe ser impactado.

La mesa de corte es otro componente importante de una cortadora láser. La superficie sobre la cual se realizará el corte; Plano. La mesa de corte cuenta con una innovadora estructura en panal que permite el flujo de aire bajo el material. Este flujo de aire ayuda a asegurar que el material plano no se mueva debido a la gravedad cuando comienza la operación de corte. Estabilizar el material es necesario para lograr cortes limpios y precisos.

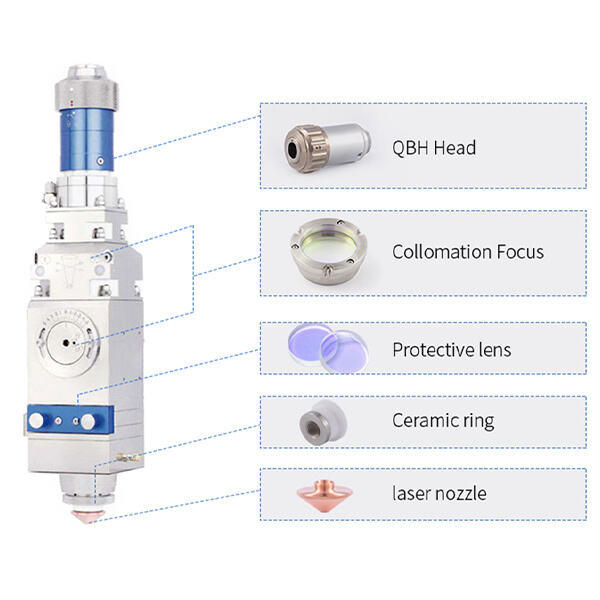

Además del tubo láser y la mesa de corte, hay otros componentes principales de una cortadora láser que hacen que funcione bien. La lente es una de estas partes. La lente de ángulo oblicuo se utiliza para enfocar el haz láser en el material. Esta acción de enfocar es crítica, ya que aumenta la densidad de energía del haz láser aplicado a la pieza de trabajo para que pueda fundir o cortar ablativamente el material.

Un panel de control que también es crucial para el funcionamiento de la cortadora láser. Aquí, el operador, la persona que usa la máquina, proporciona sus comandos. Por ejemplo, si desean hacer un corte de un tamaño y forma determinados, pueden ingresar esa información. El panel de control también ayuda a regular la potencia en vatios del láser, además de la velocidad con la que se mueve el travieso, ambos parámetros esenciales para alcanzar la meta.

Después de que el haz láser pasa a través de los espejos, la lente lo enfoca sobre el material. El haz de luz concentrado es altamente potente y capaz de fundir el material en cuestión de segundos. Con el material derritiéndose, sopla gas a través del boquilla sobre él para ayudar a limpiar las partes derretidas. Este proceso permite cortes limpios mientras también asegura que no se acumule ningún residuo que pueda interrumpir el corte.

En resumen, las máquinas de corte láser pueden hacer mucho y la versatilidad de estas herramientas es evidente en casi todas las industrias. Esencialmente, necesitas conocer las diversas partes presentes dentro de un cortador láser. Si estás buscando uno de estos, familiarizarte con estas secciones te ayudará a tomar una decisión informada.